‘It’s not about us or you. It’s about the 135 families depending on us.’

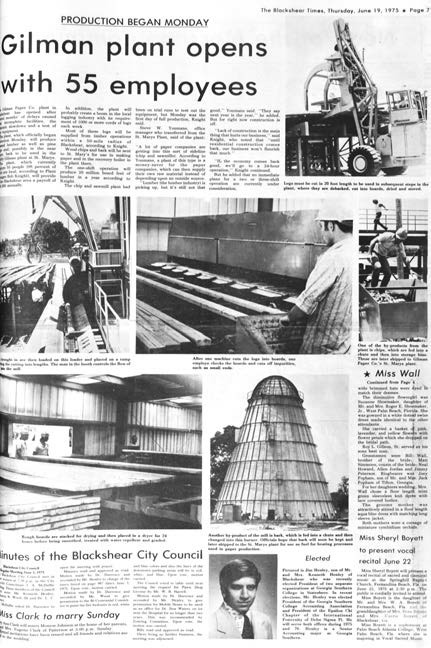

Most now know it as West Fraser Timber Company, but it began business in June 1975 as Gilman Paper Company. Whatever name you use, the wood processing plant in Blackshear has fed a lot of local families and the local economy over its 50 years of continuous operation.

Purchased September 1 2017 by West Fraser, the plant has entered a new era. What began as an operation with 55 workers has grown over the years to employ 135 people in a variety of positions.

Green End Superintendent Adam Mulkey says he always cites the last number when talking with new employees. “I tell them, this is what we expect of you, because it’s not about us or you,” says Mulkey. “It’s about the 135 families depending on us.”

Don’t think the green in Mulkey’s job title implies he is new to things at West Fraser. The Green Superintendent is in charge of the initial stages of wood processing, the crews that handle, saw and dry the raw timber before it becomes the 1x4, 2x4 and 2x6 lumber sold to various distributors. He smiles as he recalls starting out at the entry level years ago. “I’ve been here since ‘91. I’m one of the old farts now,” Mulkey chuckles. “I started out on a shovel.”

They might have started “on the shovel”, but Mulkey and Dry End Superintendent Ronnie Strickland are two of the seasoned older guard at the plant. They joke and switch back and forth answering questions with the ease of two guys who are both longtime coworkers and old friends.

According to Mulkey and Strickland, many of the “old timers” have retired in recent years and both agree they are hard to replace.

“It’s tough to overcome that loss of talent,” says Strickland, but neither seem very worried. Strickland goes on to say, “We definitely try to move people up through the company.” “It’s good work, but it is sawmilling, so it takes a special breed to work a sawmill,” Mulkey says.

The pair laugh, recalling the days when it was a requirement to have a college degree to move up the company ladder. “For a while they wanted you to have a little piece of paper to be a supervisor,” says Strickland.

“We shoveled the chips and bark to make the pieces of paper they wrote them rules on!” Mulkey laughs.

These days, on the job experience and familiarity with the ins and outs of the entire operation are more valued than formal book learning.

“Just because you don’t have sawmill experience doesn’t mean you can’t be a sawmill worker,” says Mulkey. “We got some good young men working down there right now. They didn’t know anything when they first started— but neither did I.”

Strickland feels that the strong work ethic of the farm was what made the old guard so reliable. Most of the newer employees don’t come from the farm, but Strickland says West Fraser will get anyone the training they need to succeed.

“We try to stay ahead of turnover. It’s holding its own just now, but that doesn’t mean if we found a crackerjack electrician or millwright we wouldn’t hire them,” Strickland says. “But we try to grow our own here. We train all our electricians and millwrights to be West Fraser certified.” That training and the teamwork of a close knit crew, keep West Fraser’s Blackshear location very productive.

“We’re not one of the biggest mills in our company, but we do very well,” says Mulkey. Just how well does the local Blackshear plant do? It produces approximately 125 million board feet of lumber per year. For those unfamiliar with the term, a board foot is 144 cubic inches of lumber. Imagine a piece of lumber one foot wide by one foot tall and an inch thick.

Now, multiply that by 125 million. The Blackshear plant produces nearly 18,907 miles of board feet. Laid end to end, the yearly output of the plant is equivalent to the height of 100,000 Empire State Buildings. That is a lot of lumber.

“The majority of our lumber goes to the Florida market, but I’ve see our stuff at Farmers and Builders right here in town. The treaters get it and resell it to them,” says Mulkey.

How does he know it is lumber from the West Fraser plant? Mulkey says he can identify it by the Southern Pine Inspection Bureau or “SPIB” numbers stamped on the individual sticks.

When asked about the mill’s impact on the local economy, Strickland says it is more than just lumber for hardware stores, “All the businesses in this community, there isn’t one it don’t touch. It would definitely hurt if we weren’t here.”

“We’ve got Thom’s Transport next to us,” Mulkey tips his head in the direction of the trucking company next door. “Lumber helps feed their families too.”

It is mostly locals comprising the 135 workers at the plant, but Mulkey says there are also a few out of towners, “One guy I know drives about an hour to get here.”

As for what West Fraser has in store for them in terms of its 50 year celebration, the answer is surprising. “No real plans, I guess. I haven’t heard anything,” Mulkey says, but his next words explain his seeming unconcerned, “I’m not worried. The company backs us up and supports us in everything we do. They are really good to us.”

If it is anything like the Family Day and Service Award celebrations hosted by West Fraser, it will probably go all out. September 20 is always Family Day at the mill. Workers bring their families to enjoy a day with the people they work so hard to provide for. There are games for kids and adults, bouncy houses, dunking booths, music and food.

When service awards are recognized, the company often rents out a venue like Mossy Pond to host a dinner complete with retrospective slide shows of the employees that have hit their 10, 15 and 20 or more year marks.

“They all bring their wives, we cook, do a slide show and everyone has a ball,” says Brandi White, the Blackshear plant’s office manager. “We are very family and community oriented.”

White says another sign of that close connection to the community is West Fraser’s charitable donations and local sponsorships. Bethesda House, the Ware, Pierce and Waycross Shop with a Cop programs, the PCHS band, local fire departments and others have all received support from the mill. “But if someone in the mill has a ball team and they come up to talk with Al, we help support that too,” says Mulkey.

Al is Al Cleghorn, the plant’s general manager and a 44 year veteran of West Fraser, the last four having been spent in Blackshear. Mulkey, Strickland and White all credit him and other members of their team with their success.

Safety Manager Aaron McQuaig is one of those team members. A living example of that family continuity, McQuaig’s father was the Blackshear plant’s first office manager. Now, he leads the facility in its many safety initiatives.

Blackshear received a safety reward from West Fraser for 3 full years with no recordable accidents. They also recently garnered the company’s prestigious U.S. Presidential Safety Award.

“We always honor the employees, giving them not just safety awards but also a good meal to go with it,” says White.

“We want those young men and women here to go home safe, with all ten fingers and toes,” says Strickland.

“We can get past bad days or bad production, but you have to stand on safety,” says Mulkey. “We have a truly excellent safety manager.”

As for where things go from here, all three feel confident things are headed in the right direction. Mulkey sums up the sense of stability and continuity that has been the roots of the lumber mill for decades, “I started when I was 21 and have been through all the changes. I got married, had kids, raised them up, got them through school. Now I want to see these new guys make a living out of it. It’s our job to pass on our knowledge and work ethic.”